Source factory & No middleman !

Lithium Battery Manufacturers

- Flexible MOQ, supporting small batch customization and scalable production

- Various types of replacement batteries

- When the order quantity reaches a certain level, we can provide free custom mold opening.

- Personal engineer for full one-on-one support

SKQ has more than 10 years of experience in the lithium battery manufacturing industry and has its own mold room.

SKQ has multiple production lines, automatic sorting machines, automatic spot welding machines, comprehensive testers, aging cabinets and other high-end production equipment.

From communication to order confirmation, product production and processing and after-sales have exclusive engineers and you docking!

Our lithium battery packs

Our lithium battery packs are widely used in small appliances, consumer electronics, lighting, two- & three-wheel vehicles, and home energy storage.

We also provide replacement batteries for various products, making it easier for e-commerce sellers and distributors to purchase in small wholesale quantities.

Standard and customized battery packs compatible with multiple e-bike brands

- Voltage options: 36V/48V, capacity 10Ah–30Ah

- Compatible with mainstream e-bike motors and controllers

- Li-ion / LiFePO₄ cells, 800–2000+ cycles

- Integrated BMS with multiple protection features

- OEM/ODM customization available for brands and distributors

Compatible with solar street lights, off-grid systems, and small energy storage applications

- Available in 12V/24V/48V systems, capacity 50Ah–200Ah+

- Reliable energy storage for solar, off-grid and backup systems

- LiFePO₄ cells, 3000–6000+ cycles

- Equipped with BMS: cell balancing and multiple protection features

- Low maintenance, eco-friendly solution for long-term use

Reliable energy storage solutions for outdoor, home, and small business applications

- 1000W continuous pure sine wave output, suitable for electronics and small appliances

- Approx. 1000Wh capacity, supporting outdoor work, emergency backup and light commercial use

- LiFePO₄ cells, >3000 cycles, high safety and long lifespan

- Multiple output ports (AC/USB/DC), suitable for diverse application scenarios

- Rechargeable via AC, car input, or solar (MPPT available)

Battery solutions for vacuum cleaners, robot mowers, and household tools

- Suitable for vacuum cleaners, robot mowers, garden tools, etc

- Li-ion/LiFePO₄ cells, 500–2000+ cycles

- Stable discharge curve for consistent device operation

- Built-in BMS: short circuit, overcharge/discharge protection

- Custom shapes and connector types available

Replacement and custom battery packs compatible with multiple scooter brands

- Voltage options: 24V/36V, capacity 5Ah–20Ah

- Li-ion cells, 500–1000+ cycles

- BMS with overcharge, over-discharge and short circuit protection

- Compatible with major scooter brands, OEM customization available

- Bulk supply for distributors and rental fleet operators

Replacement and bulk supply for cameras, drones, and communication devices

- Voltage and capacity customized per application (e.g. cameras, drones, communication

- Consistent discharge performance for professional equipment

- Li-ion cells, 500–1000+ cycles

- Integrated protection board ensuring safety and reliability

- Available in standard and custom pack designs for OEM projects

Fully Customizable

Custom lithium battery packs are more suitable for your project

- We understand every project is different. That’s why we customize voltage, capacity, and size to make sure the battery fits your device and system perfectly.

- If you need longer runtime or higher efficiency, we optimize the discharge curve and energy density to deliver exactly the performance you expect.

- To help you reduce after-sales issues, we use high-quality cells and proper thermal design, giving your battery a much longer cycle life.

- Safety is always our priority. That’s why we integrate a customized BMS to protect against overcharge, short circuit, and imbalance.

- We know differentiation is important. Our OEM/ODM design service helps your product stand out and build your own brand advantage.

- In the long run, a well-designed battery saves cost. With fewer replacements and less downtime, you get higher value from every project.

Why choose us?

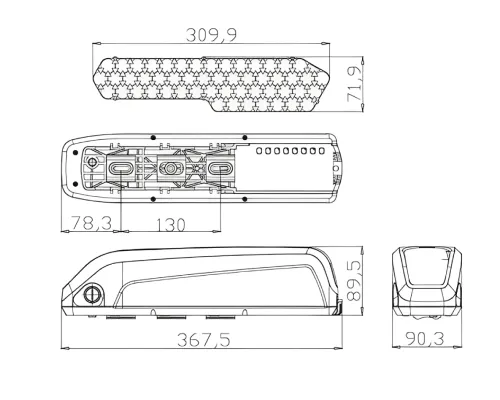

Free Battery Design (with 3D Drawings)

We provide free battery design for standard solutions, including 3D drawings to accelerate your project development.

Comprehensive Quality Control

Every project undergoes structural review, sample evaluation, and pre-production testing, including cycle, vibration, and waterproof tests (if required).

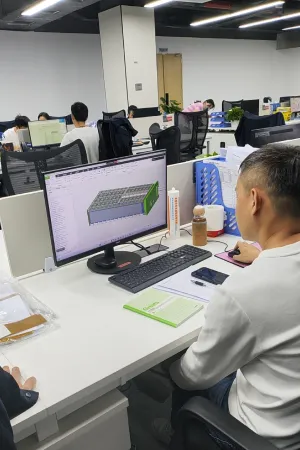

Experienced Engineering Team

Our core engineers each have over 5 years of hands-on experience in lithium battery PACK design and manufacturing.

Highly Customized Appearance Options

We offer various surface finishing options, such as painting, polishing, and electroplating, to meet customers’ personalized appearance requirements.

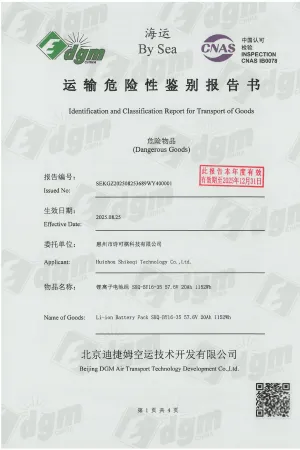

Complete Certifications

Our batteries are fully certified, meeting international standards and compliance for global markets.

In-house Molding, Free Tooling with MOQ

With our in-house molding workshop, we offer free tooling when the order quantity reaches the required MOQ, helping customers reduce development costs.

About SKQ

Huizhou Shikeqi Technology Co., Ltd. is located in Huizhou, Guangdong, with a modern manufacturing facility of around 5,000 square meters. Our strategic location provides convenient access for both domestic and international clients.

We are equipped with advanced production and testing equipment, including automatic sorting machines, spot welding machines, integrated testing systems, aging cabinets, automatic labeling, and packaging machines. These facilities ensure high consistency and reliable quality throughout the manufacturing process.

Our product portfolio includes lithium batteries for 3C digital devices, small household appliances, two-wheeled vehicles, and home energy storage systems. These solutions are widely applied in consumer electronics, smart home, mobility, and renewable energy sectors.

Common Questions

Most Popular Questions.

We have listed some questions you may ask. If you have more inquiries about our products, you can send an inquiry to contact us.

Compliance and safety are the foundation of our collaboration. Our core products are certified to key international standards including UL, CE, UN38.3, and RoHS. Furthermore, we provide comprehensive technical documentation support, including detailed specifications, certification copies, and MSDS (Material Safety Data Sheets), to fully assist with your product compliance and market access.

We provide references based on objective test data (Standard test conditions: 0.5C, 25°C, 100% DoD):

· LiFePO4 (LFP): Longer cycle life, typically 1,500 – 2,000 cycles (to ≥80% capacity retention).

· NMC: High energy density, with a typical cycle life of 500 – 1,000 cycles (to ≥80% capacity retention). Actual lifespan is highly dependent on the application environment,discharge rate, and temperature. We welcome your specific operating conditions for a more accurate assessment.

We provide a detailed technical package to ensure your team has all necessary information for integration, including:

· Product Specification Sheets

· Certification Documentation

· BMS Communication Protocols

· 3D Model Files and mechanical drawings

· Test Samples for your practical validation Our engineering team will actively cooperate to answer any technical questions.

We follow a clear custom development process for efficient project progression:

1. Requirements Confirmation: Please provide detailed needs: e.g., voltage, capacity, size constraints, max continuous discharge current, peak current, communication interface, application environment, etc.

2. Proposal & Quotation: We provide a technical solution, quotation, and lead time after evaluation.

3. Sampling & Testing: We produce samples for internal testing before sending them to you for validation.

4. Mass Production & Delivery: Upon sample approval, we proceed with batch production and delivery. To ensure production efficiency,the MOQ for custom projects is tentatively set at 50 units, which is negotiable.

We provide reliable and clear delivery schedules:

· Standard Products: Approximately 7 working days if in stock.

· Custom Products: The first production run typically requires 3-4 weeks (includes material procurement, production, and full inspection time). The exact delivery date will be provided in writing upon order confirmation,and we adhere strictly to our commitments.

We ensure stability through systematic quality control:

· Strict Incoming Quality Control (IQC): Batch inspection of key materials like cells, PCBs, and connectors.

· Full-Process Control (IPQC): Quality checkpoints at key stages (welding, assembly, curing).

· 100% Testing & Sampling (FQC/OQC): 100% of finished products undergo voltage, internal resistance, and load performance tests, supplemented by regular sampling for cycle aging tests. We are committed to quality transparency and can provide inspection reports for key stages.

Want to find the source factory to save money in the middle?

We have a source factory that can customize lithium batteries and have many years of production experience. Choosing us can maximize our interests.

Get Your Battery Quote in 12 Hours

Factory-direct price and fast engineering response.

Fill out the form and get your best offer today.